Welded stainless steel pipe provides us a large diameter but low cost solution. Our welding process mainly is Plasma-Arc Welding(PAW), its biggest diameter could reach 3000mm. If other process is required, please state it in the requirement of stainless steel tubings.

Stainless steel contains chromium which provides the properties of corrosion resistance at high temperatures. Stainless steel can withstand corrosive or chemical environments due to its smooth surface. Stainless steel products are safe for long-term use with excellent resistance of corrosion fatigue.

Available Grade:

- TP304,304L,304H,316,316L,316H,316Ti,317,317L,309S,310S,310H,347,347H,321,321H,904L, S31254.(mat.1.4301,1.4307,1.4948,1.4401,1.4404,1.4571,1.4438,1.4438, 1.4833,1.4841,1.4845,1.4845,1.4450,1.4541,1.4878,1.4539, ,1.4547/254SMO) etc.

(If your required is not found here, please make a special enquiry immediately. Our team will reply in time.)

Welded Pipe’s Surface Finishes:

- Pickling finish

- bright annealed finish

- Mirror finish

- sand blast finish

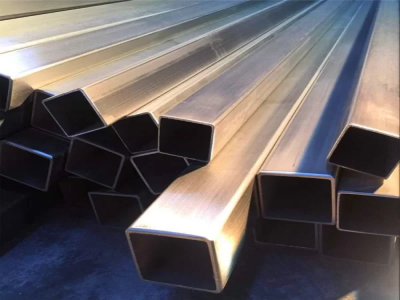

Our Range Covers of Welded Stainless Steel Pipes:

Outer diameters from 6 up to 3000 mm (0.24 up to 118 inches) and

wall thicknesses from 0.5 up to 36 mm (0.02 up to 1.42 inches).

Stainless Steel Pipes Catalog

*If you require welded stainless steel pipe, please contact us and we will be happy to help you order what you need. We are also available to answer questions about our stainless steel pipe or any other products.

Application

Stainless steel seamless pipe can resist high temperatures for cleanliness and maintain the purity of materials which contact stainless steel directly. Stainless steel pipe and tubing are used in chemical plants, petroleum refining, marine building, LNG, medical, machinery Manufacturing etc.

- Petroleum refining

- Marine and Ship Buidling

- Chemical plants

- Fertilizer plant

- LNG construction

- Machinery Manufacturing

- Civil Engineering

- Water treatment