Seamless stainless steel tubing is a highly versatile and durable material widely used across various industries due to its excellent corrosion resistance,high-temperature performance,and mechanical strength.This type of tubing is characterized by its hollow cross-section and lack of seams,making it ideal for applications requiring high pressure and strength.Whether you’re in the petrochemical,food,and medicine,energy and power,building decoration, or automobile manufacturing industry,seamless stainless steel pipe offers unmatched reliability and performance.

Seamless Stainless Steel Tubing

Stainless steel seamless tube is a kind of long steel with a hollow cross section and no seams around it. The thicker the wall thickness of the product, the more economical and practical it is, and the thinner the wall thickness, the processing cost of it will rise substantially.

The process of the product determines its limited performance, general seamless steel pipe precision is low: wall thickness is not uniform, low brightness of the inner appearance of the tube, high cost of sizing, and the inner appearance of the pockmarks, black spots are not easy to remove; its detection and shaping must be processed offline. Therefore, it reflects its superiority in high-pressure, high-strength, mechanical structure materials.

Definition of seamless stainless steel tubing

Seamless stainless steel pipe is a type of stainless steel pipe made by hot or cold rolling process, which is characterized by the absence of welded seams and has excellent corrosion resistance, high temperature resistance and mechanical properties.

Types

Classification by use

Structural seamless stainless steel pipe: used for construction, machinery and other structural parts.

Seamless stainless steel pipe for fluid transportation: used for transportation of water, oil, gas and other fluids.

Boiler seamless stainless steel pipe: used for boilers and heat exchangers.

Seamless stainless steel pipe for chemical industry: used for chemical equipment, corrosion resistance.

Classification by material

Austenitic stainless steel pipe: such as 304, 316, good corrosion resistance.

Martensitic stainless steel tube: such as 410, 420, high hardness.

Ferritic stainless steel tube: such as 430, strong magnetism.

Duplex stainless steel tube: such as 2205, both austenitic and ferritic properties.

Manufacturing Methods

Hot rolling method:

Billets are heated and then pierced, rolled and sized, suitable for large diameter thick-walled pipes.

Cold rolling method:

Hot rolled billets are cold rolled and cold drawn, suitable for small diameter thin-walled pipes with high precision.

Extrusion method:

Billets are heated and then extruded, suitable for complex cross-section pipes.

Fields Of Application

Petrochemical industry: used for conveying corrosive media.

Food and medicine: used in piping systems with high hygiene requirements.

Energy and power: used in boilers, heat exchangers and other high-temperature and high-pressure environments.

Building decoration: used for structural components and decorative materials.

Automobile manufacturing: used in exhaust system, fuel system, etc.

Common Dimension in Stock

Seamless Stainless Steel Tubing Standards

Chinese Standard

GB/T14976: Seamless stainless steel pipes for fluid transportation.

GB/T13296: Seamless stainless steel tubes and pipes for boilers and heat exchangers.

GB/T12771: Stainless steel seamless pipes for structural use.

International Standard

ASTM A312: Seamless and welded austenitic stainless steel tubing.

ASTM A269: Seamless and welded austenitic stainless steel tubes for general purposes.

EN 10216-5: Seamless stainless steel tubes and pipes for pressure purposes.

Calculation Formula

Wall Thickness

Among them:

t: Wall Thickness (mm)

P: Design Pressure (MPa)

D: Outer Diameter (mm)

S: Permissible Material Stress (MPa)

E: Weld Coefficient (1 FOR SEAMLESS PIPE)

Y: Material Coefficient

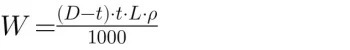

Weight

Among them:

W:Weight (kg)

D:Outer Diameter (mm)

t: Wall Thickness (mm)

L: Length (m)

ρ: Density Of Stainless Steel (kg/m³, USUALLY 7930)

Dimension Range

Seamless stainless steel tubes are available in a wide range of sizes including outside diameter, wall thickness and length.

Outer Diameter Range

Seamless Stainless Steel Pipe has a wide range of outer diameters, covering from small to large caliber:

Small caliber: 6mm to 20mm are common, such as 6mm, 8mm, 10mm, 12mm, 14mm, 16mm, 18mm, 20mm, etc.

Medium caliber: 20mm to 100mm, such as 22mm, 25mm, 28mm, 30mm, 32mm, 34mm, 38mm, 40mm, 42mm, 45mm, 48mm, 50mm, 51mm, 57mm, 60mm, 63mm, 65mm, 70mm, 73mm, 76mm, 80mm, 83mm, 89mm, 90mm, 95mm, 100mm and so on.

Larger caliber: 100mm to 300mm, such as 102mm, 108mm, 114mm, 121mm, 127mm, 133mm, 140mm, 146mm, 152mm, 159mm, 168mm, 170mm, 180mm, 192mm, 194mm, 200mm, 219mm, 245mm, 250mm, 273mm and so on.

Large caliber: above 300mm, such as 325mm, 355mm, 377mm, 406mm, 426mm, 457mm, 508mm, etc.

Wall Thickness Range

Wall thickness varies according to the outer diameter:

Thin wall: 0.4mm to 2mm, common for small diameter pipes.

Medium wall thickness: 2mm to 10mm, commonly found in medium caliber pipes such as 3mm, 4mm, 5mm, 6mm, 8mm, 10mm, etc.

Thick wall: 10mm to 30mm or even thicker, commonly found in large caliber pipes, such as 12mm, 14mm, 15mm, 16mm, 18mm, 20mm, 22mm, 25mm, 30mm, 34mm, etc.

Length Range

The length of seamless stainless steel pipe varies depending on the production process:

Hot rolled steel pipe: the length is usually 1.5m to 10m.

Hot extruded steel pipe: the length is usually more than 1m.

Cold-drawn (rolled) steel pipe: the length is 1.0-7m for wall thickness 0.5-1.0mm; the length is 1.5-8m for wall thickness greater than 1.0mm.

Get A Free Quote >>>>>>>>>>>>>>>>>>>>