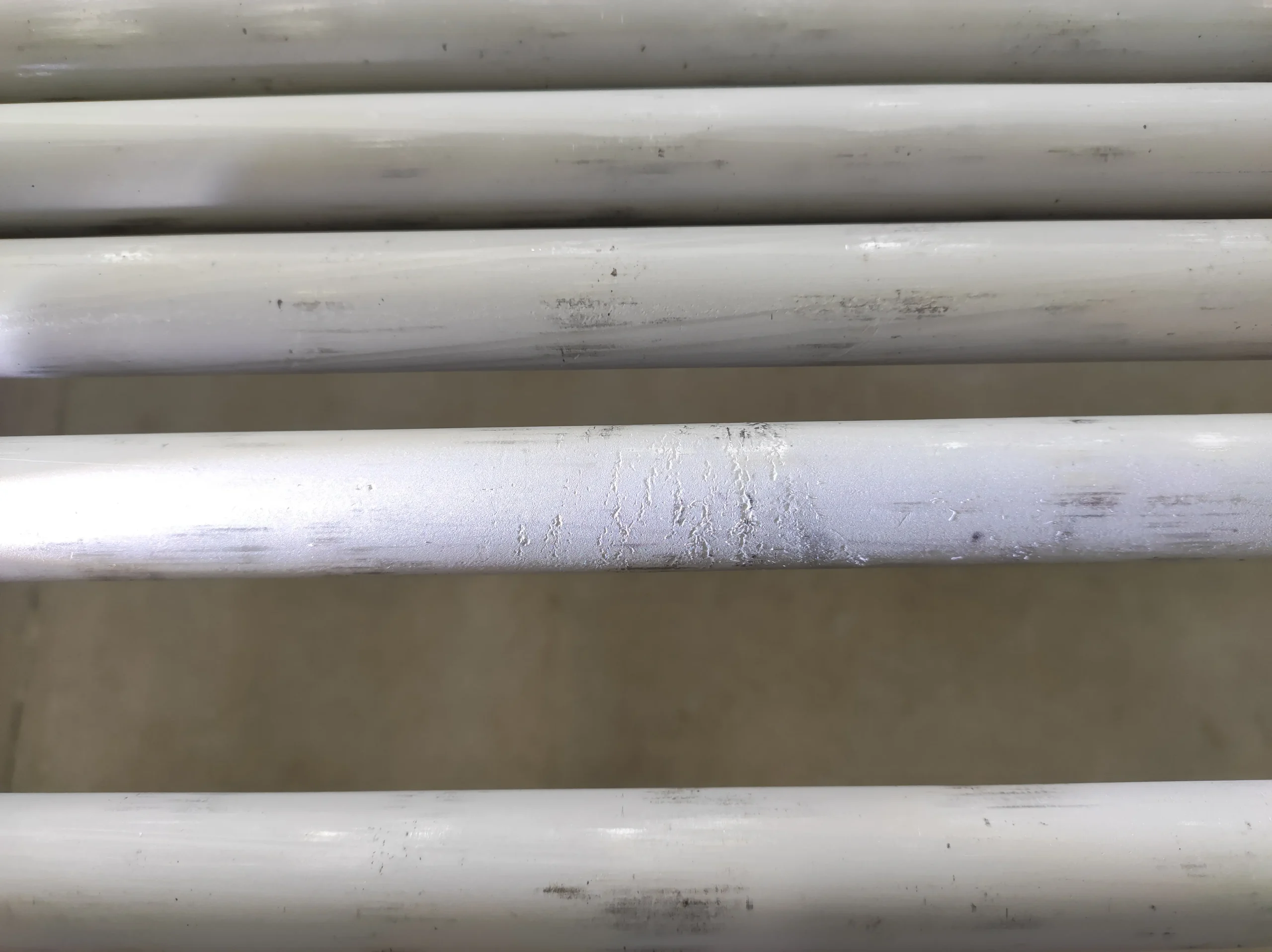

Никель-хром-железные сплавы, сокращенно NiCrFe сплавы. Они известны своей высокой прочностью, устойчивостью к коррозии и окислению. В составе преобладает никель или железо, что определяет специфику его применения. Инконель 600на основе никеля и Incoloy 800 на основе железа.

Применение сплавов никель-хром-железо

Эти сплавы широко применяются в средах, где требуется высокая температура или устойчивость к коррозии. Например, в химической промышленности, энергетике и пищевой промышленности. Кроме того, они могут использоваться для изготовления нагревательных элементов и проводов сопротивления, как, например, некоторые железосодержащие никель-хромовые сплавы.

Сплавы на основе никеля (например, Inconel 600) широко используются в аэрокосмической промышленности и газовых турбинах.

Сплавы на основе железа, такие как Инколой 800С другой стороны, они в основном используются в химической и строительной промышленности.

Противоречивость и сложность сплавов никель-хром-железо

Классификация сплавов NiCrFe может быть противоречивой из-за различий в соотношении компонентов. В промышленности их иногда классифицируют как сплавы на основе никеля или железа, что может привести к путанице в названиях и использовании.

Заказать товары

Определение и состав сплавов никель-хром-железо

Определение более широкое, и исследования показали, что это смесь металлов, содержащих никель, хром и железо. Исходя из соотношения компонентов, мы делим его на две категории:

Сплавы на основе никеля: Никель является основным компонентом, а хром и железо - легирующими элементами.

Сплавы на основе железа: Железо в качестве основного компонента, никель и хром в качестве легирующих элементов.

| Никель (%) | Хром (%) | Железо (%) |

|---|---|---|

| 60.5 | 23 | 13 |

| 70 | 15.5 | 7 |

| 72 | 15.5 | 8 |

| 77 | 15.5 | 7.5 |

Подробные примеры и сравнение

| Название сплава | Основные ингредиенты (%) | Основной металл | Типовые применения |

|---|---|---|---|

| Инконель 600 | Ni 72, Cr 14-17, Fe 6-9 | Никель | Аэрокосмическая промышленность | Газовые турбины |

| Инколой 800 | Fe 45-55, Ni 30-35, Cr 19-23 | Железо | Химическая промышленность | Пищевая промышленность |

Свойства и характеристики

Он ценится за высокую прочность, устойчивость к коррозии и окислению. Хром повышает устойчивость к коррозии и окислению за счет образования поверхностной пленки Cr2O3, которая особенно подходит для высокотемпературных сред. Сплавы на основе никеля могут выдерживать температуру до 1200°C. Напротив, сплавы на основе железа демонстрируют отличные свойства ползучести и разрушения под напряжением в диапазоне 600-800°C.

Кроме того, некоторые из них обладают высоким удельным сопротивлением и широко используются в нагревательных элементах и проводах сопротивления. Например, нихром А не содержит железа, но некоторые составы, такие как нихром V, содержат железо.

Сплавы NiCrFe - это высокоэффективные сплавы, определение которых охватывает широкий спектр составов на основе никеля или железа. Эти сплавы используются не только в промышленном оборудовании, но и в предметах быта, что является неожиданной деталью.

Возможно, вы также захотите прочитать:

Краткое руководство по сплавам на основе никеля для промышленного использования, Все о коррозии

Что такое никель-хром-молибденовая сталь?

Связаться с нами

- RM901 No.22 Tangjiaqiao Road Wenzhou Китай

- +86 577 8551 1171

- [email protected]

- https://www.kaysuns.com/