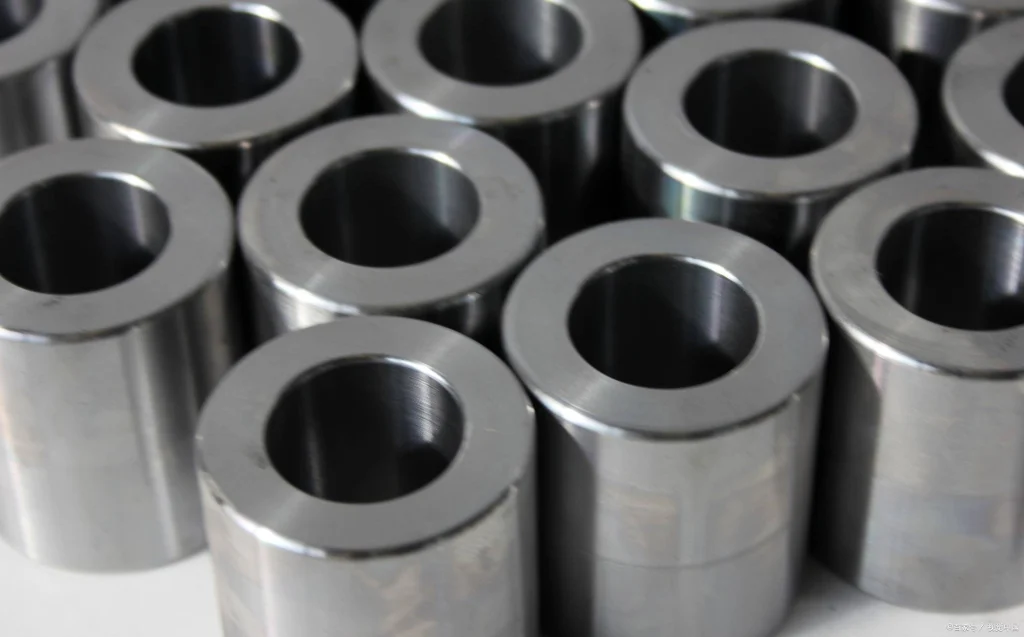

A286 alloy, also known as Incoloy A-286 or UNS S66286, is a Fe-25Ni-15Cr-based high-temperature alloy renowned for its exceptional high strength, creep resistance, oxidation resistance, and weldability. This alloy excels in extreme heat, making it a top choice for applications in aerospace, automotive, and industrial sectors.

Химический состав

The remarkable performance of A286 stainless steel alloy stems from its well-balanced chemical composition. It contains 13-16% chromium and 24-27% nickel as its primary elements, along with molybdenum (1-1.5%), cobalt (1%), vanadium (0.10-0.5%), titanium (2%), manganese (2%), silicon (1%), aluminum (0.35%), carbon (1%), and trace amounts of phosphorus (0.025%) and sulfur (0.025%).

This unique blend provides A286 stainless steel alloy with outstanding mechanical strength and corrosion resistance. It maintains high strength up to 1300°F (700°C) and offers excellent oxidation resistance up to 1500°F (815°C). While not suited for highly acidic environments, it performs exceptionally well under conditions like high-temperature exhaust streams.

Applications Of A286

Thanks to its creep resistance and oxidation resistance, A286 alloy is widely used in components that operate under extreme heat, including:

- Аэрокосмическая промышленность: Turbine engine parts, fasteners, and springs.

- Автомобильная промышленность: Exhaust systems and high-temperature bolts.

- Industrial: High-temperature equipment and piping systems.

These properties make A286 alloy an ideal material for demanding environments where reliability and durability are critical.

Workability And Weldability

A286 alloy outperforms austenitic stainless steels in hot working. It can be rolled or forged at temperatures between 1900-2050°F (1038-1121°C), though forging below 1700°F (927°C) should be avoided to prevent increased deformation resistance. In cold working, it is less workable than SUS316 or SUS310 but easier to process than nickel-based precipitation-hardened steels (e.g., Alloy 718) or cobalt-containing grades (e.g., Alloy 41). Additionally, A286 alloy offers good weldability, supporting processes like argon arc welding, spot welding, and seam welding. Post-weld aging treatment is typically applied to enhance its properties.

Standards Of A286

A286 alloy meets rigorous international standards, including AMS 5731, AMS 5737, AMS 5853, and ASTM A638, ensuring consistent quality and performance. Common designations include Incoloy A-286, GH2132 (Chinese standard), UNS S66286, and W.NR 1.4980.

Comparison with Other High-Temperature Alloys

Compared to austenitic stainless steels, A286 alloy offers superior high-temperature strength and creep resistance. While it may not match the extreme performance of nickel-based alloys, it provides a cost-effective and easier-to-process alternative, striking an excellent balance for various applications.

Trends Of A286

As demand for high-temperature materials grows in industries like aerospace and automotive, A286 alloy is poised for expanded use. Advances in manufacturing techniques may further enhance its performance and reduce production costs, solidifying its position as a leading high-temperature alloy.

A286 alloy is a high-performance material that excels in high-strength, creep-resistant, and oxidation-resistant applications. Its weldability and compliance with strict standards make it a reliable solution for aerospace, automotive, and industrial needs. Whether for turbine components or exhaust systems, A286 alloy delivers unmatched performance in extreme conditions.

Связаться с нами

Свяжитесь с нами

- RM901 No.22 Tangjiaqiao Road Wenzhou Китай

- +86 577 8551 1171

- [email protected]

- https://www.kaysuns.com/

Найти нас