Сплав 59 (UNS N06059) — это никель-хром-молибденовый сплав с ультранизким содержанием углерода, демонстрирующий высочайшее качество. коррозионная стойкость. Он хорошо переносит воздействие агрессивных кислот и высокотемпературных галогенидов. Таким образом, сплав 59 является оптимальным выбором для труб и фитингов из нержавеющей стали в химической и морской промышленности.

Химический состав сплава 59

| Элемент | Ni | Cr | Пн | Fe | C | Mn | Si | п | S | Al |

|---|---|---|---|---|---|---|---|---|---|---|

| Содержание (%) | Остаток средств | 22.0-24.0 | 15.0-16.5 | ≤1.5 | ≤0.01 | ≤0.5 | ≤0.1 | ≤0.015 | ≤0.005 | 0.1-0.4 |

Основные преимущества сплава 59

Значение PRE достигает 75, что идеально подходит для труб из нержавеющей стали, содержащих кислоту.

Не требуется предварительный нагрев, что сокращает расходы на трубопроводную арматуру.

Прочность на разрыв ≥690 МПа, удлинение ≥40% обеспечивают безопасность трубы.

Хорошо работает при высокой температуре, идеально подходит для труб теплообменников.

Высокая долговечность снижает затраты на обслуживание систем из нержавеющей стали.

Стандарты сплава 59

- UNS: N06059

- EN: 2.4605

- ASTM: B622 (бесшовные трубы), B626 (сварные трубы)

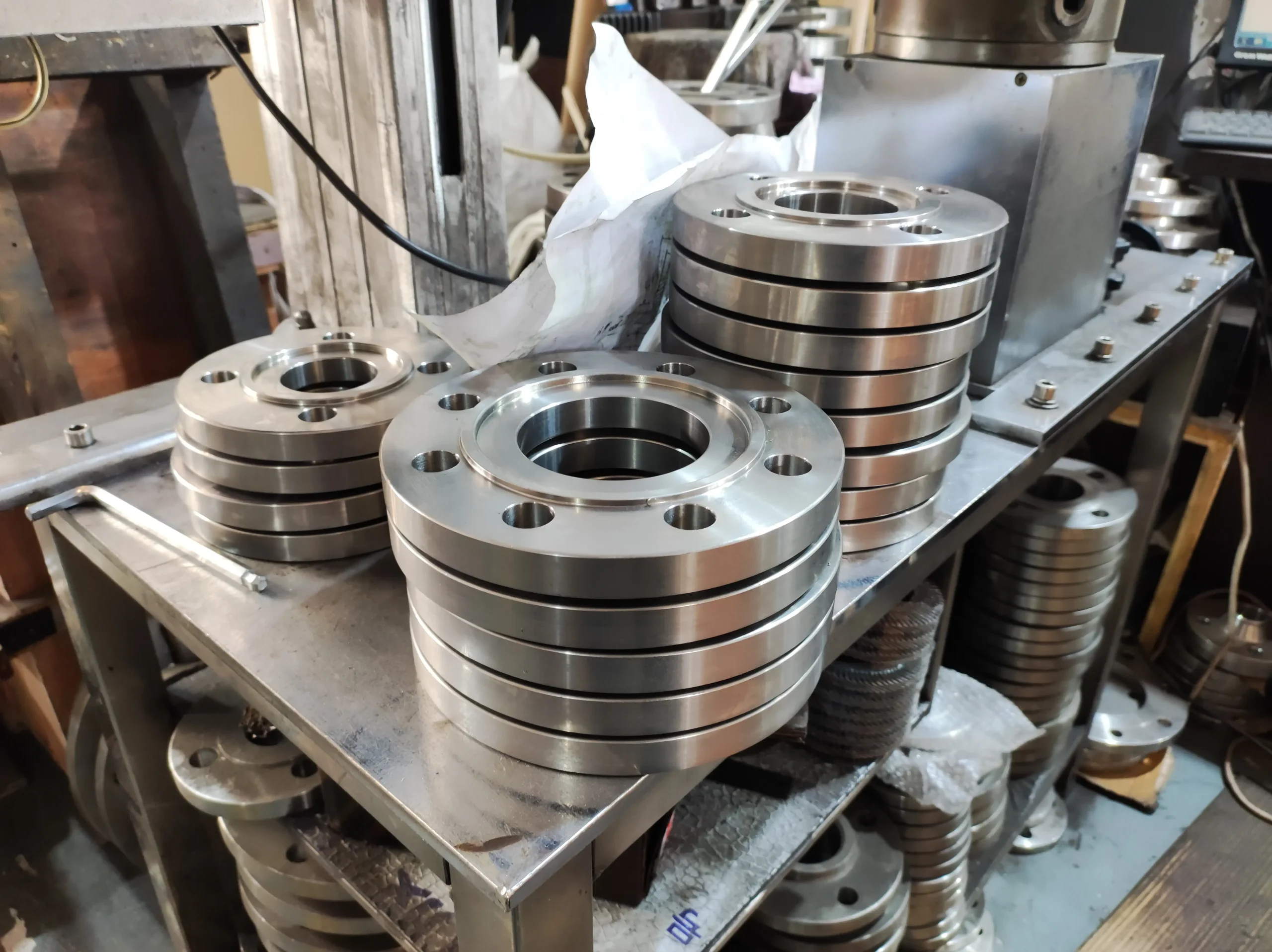

Что мы делаем

Применение сплава 59

- Химический редуктор: Реакторы PTA работают 15 лет в уксусной кислоте, насыщенной бромидами.

- Экологическое использование: Скрубберы устойчивы к кислотному конденсату pH 0,5-2.

- Морские системы: Глубоководные трубы остаются прочными на глубине 3000 м.

- Трубы и фитинги из нержавеющей стали: Сплав 59 повышает долговечность в экстремальных условиях.

Механические свойства сплава 59

| Имущество | Прочность на разрыв (Rm) | Предел текучести (Rp0.2) | Удлинение (A) | Твердость (HB) |

|---|---|---|---|---|

| Ценить | ≥690 МПа | ≥310 МПа | ≥40% | ≤230 |

Особенности обработки

- Горячая штамповка: Используйте 1050-1200°C, при этом 1150°C идеально подходит для раскатки.

- Холодная обработка: Коэффициент упрочнения n=0,35 превосходит аналогичные сплавы.

- Термическая обработка: Закалка при 1120-1170°C для получения твердого раствора.

Особенности фазового состава

- Матрица: Однофазный аустенит позволяет избежать риска выпадения интерметаллических осадков.

- Коррозионный щит: Cr₂O₃/MoO₃ пленка остается стабильной от pH 0 до 14.

- Значение PRE: 71-75, превосходя по этому показателю ведущие промышленные сплавы.

Коррозионная стойкость в экстремальных условиях

- Соляная кислота: Скорость коррозии остается ниже 0,1 мм/год при 40°C, концентрация 40%.

- Серная кислота: Скорость снижается до 0,03-0,05 мм/год при 80°C, концентрация 93-98%.

- Хлориды: Температура питтинга превышает 100°C, при щелевой коррозии CL=85.

Техника сварки

- Топ-метод: Лучше всего подходит GTAW с проволокой ERNiCrMo-13.

- Ключевые советы:

- Поддерживайте температуру интерпаса ниже 150°C.

- Пропустите предварительный нагрев и послесварочная обработка.

- Используйте аргоновый экран, кислород не должен превышать 50ppm.

Сплав 59 VS. Конкуренты

| Сплав | Значение PRE | CPT (°C) | CL | Прочность на разрыв (МПа) |

|---|---|---|---|---|

| Сплав 59 | 71-75 | >100 | 85 | ≥690 |

| Сплав 625 | 50 | 80 | 60 | ≥760 |

| Сплав C276 | 69 | 90 | 75 | ≥690 |

| 316L | 24 | 20 | 10 | ≥485 |

Связаться с нами

- RM901 No.22 Tangjiaqiao Road Wenzhou Китай

- +86 577 8551 1171

- [email protected]

- https://www.kaysuns.com/