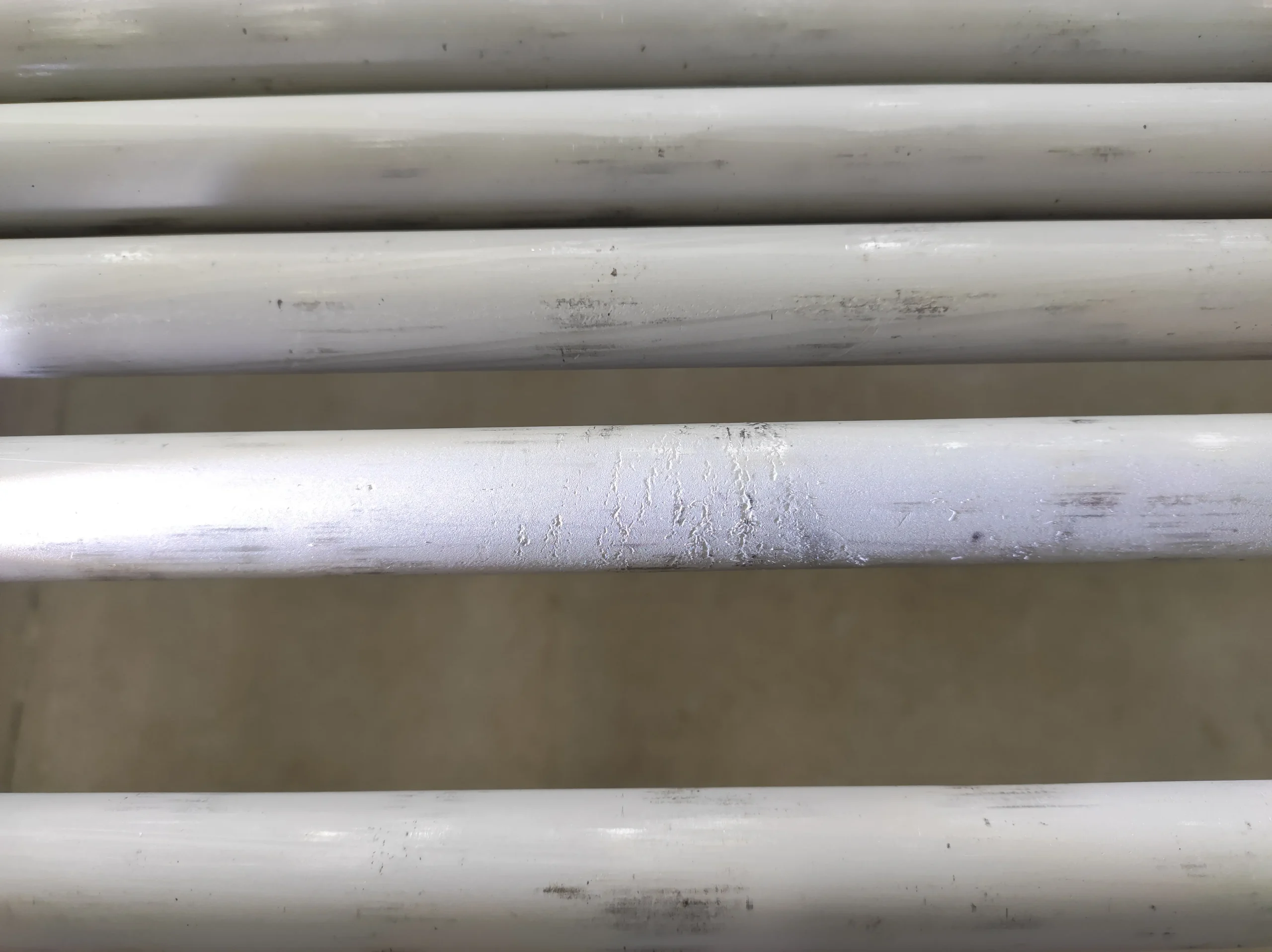

The chemical heat treatment of Duplex 2507 stainless steel

Chemical heat treatment of Duplex 2507 is mainly the formation of active atoms: the active atoms are absorbed by the metal surface and the active atoms diffuse into the metal.

The speed of these three processes is not only related to the carburizing agent used, but also closely related to the temperature and time during chemical heat treatment.

The effect of heating temperature: The decomposition rate of carburizing agent is closely related to the heating temperature. Generally speaking, when the heating temperature is higher, the decomposition rate of the carburizing agent is faster, and the more active atoms are formed. Therefore, all chemical heat treatments are mostly carried out in a higher temperature range. However, because there are many types of 2507 stainless steel chemical heat treatment, many of them are carried out at lower temperatures, such as low-temperature cyanidation and vulcanization. However, it should be noted that if the temperature is too high, the metal crystal grains will grow rapidly, and a high concentration of diffusion layer will appear. In this case, the performance of the base metal and the performance of the diffusion layer will deteriorate. Therefore, chemical heat treatment is carried out within a certain temperature range.

Effect of heating time: In the chemical heat treatment of duplex 2507 pipes, if the heating temperature is constant, the longer the diffusion time, the greater the depth of the diffusion layer. However, after the depth of the diffusion layer increases to a certain value, it gradually attenuates with time, or even stops.

Posted by stainless steel pipe fittings supplier, KAYSUNS.