Description of Super Duplex Stainless Steel 2507

Super Duplex Stainless Steel 2507 contains 25% chromium, 4% molybdenum and 7% nickel. It is of strong intensity and corrosion resistance, and is mainly used in chemical processing, petrochemical and subsea equipment. Besides, this stainless steel is also resistant to chloride corrosion, high thermal conductivity and low coefficient of thermal expansion. With high content chromium, molybdenum and nitrogen, it can resist spot corrosion, crack corrosion and general corrosion.

Super Duplex 2507 also has a very high impact strength. But it cannot be used under the temperature of 570 Degree. If putting it under this environment for a long period of time, its intensity will be decreased. This stainless steel integrated with many advantages of ferritic steel and austenitic steel. Due to high content of chromium and molybdenum, it has excellent resistance to corrosion, crevice corrosion and the ability of uniform corrosion. Duplex microstructure also guaranteed that it can resist to stress corrosion cracking, and the mechanical strength is high.

ASTM: UNS S32750

DIN: 1.4410

GB: 00Cr25Ni7Mo4N

Forging Grade: F53

II. Chemical Component

| C≤ | Si≤ | Mn≤ | P≤ | S≤ | Cr≥ | Ni≥ | Mo≥ | N≤ |

| 0.03 | 0.80 | 2.00 | 0.030 | 0.020 | 24.0-26.0 | 6.0-8.0 | 3.0-5.0 | 0.24-0.32 |

| Other | PREN | Fe≤ | Cu≤ | Al≤ | Ti≤ | Nb≤ | W≤ | V≤ |

| * | 0.05 | – | – | – |

*PREN: %Cr + 3.3x%Mo + 16x%N

III. Physical and Mechanical Function

- (a) Density of 2507: 8.0g/cm3.

- (b) Tensile strength of duplex 2507: σb≥ 800MPa.

- (c) Yield strength of 2507: σ0.2≥550Mpa

- (d) Elongation of 2507: δ≥15%.

- (e) Hardness of 2507: 310

IV. Corrosion Resistance

(a) Compared with normal corrosion and 904L, super duplex stainless steel 2507 is more powerful in its corrosion resistance on sulfuric acid mixed with chloride ions. For 904L, it is an austenitic alloy specially designed to resist the corrosion of pure sulfuric acid. However, super duplex stainless steel 2507 has ability to resist both organic acids such as formic acid and acetic acid and inorganic acids, with the help of high chromium and molybdenum content. As for 316L, it cannot be used in hydrochloric acid environments, where it may be subject to local or global corrosion. Super duplex stainless steel 2507 can be used in dilute hydrochloric acid environment because it has a strong resistance to spot damage and crack corrosion.

(b) Intergranular corrosion: Due to lower carbon content in super duplex stainless steel 2507, the risk of intergranular carbide precipitation during heat treatment thus is greatly reduced. Therefore, this alloy has a strong resistance to carbide-related intergranular corrosion.

(c) Cracking caused by stress corrosion: Due to its higher alloy content, the corrosion resistance and strength of 2507 are better than 2205. The compound structure of 2507 makes itself have strong stress corrosion cracking resistance.

(d) Corrosion resistance: There are many ways to test the corrosion resistance ability of steel products in the solution containing chloride. And the critical temperature for high-performance stainless steel in the solution of 1M sodium chloride is specified. All kinds of experimental results have shown that 2507 has excellent corrosion resistance ability.

(e) Crack corrosion: For every construction, crack is always inevitable, which thus makes stainless steel in the chloride environment is more vulnerable to corrosion. Super duplex stainless steel 2507 has a strong crack corrosion resistance.

V. Applications:

(a) Oil and gas industry equipment

(b) Off-shore platform, heat exchanger, underwater equipment, firefighting equipment

(c) Chemical processing industry, utensils and piping industry

(d) Desalination plants, high pressure RO plants and submarine pipelines

(e) Mechanical parts (high strength, corrosion resistance parts)

(f) FGD system in energy industry, industrial cleaning system, absorption tower

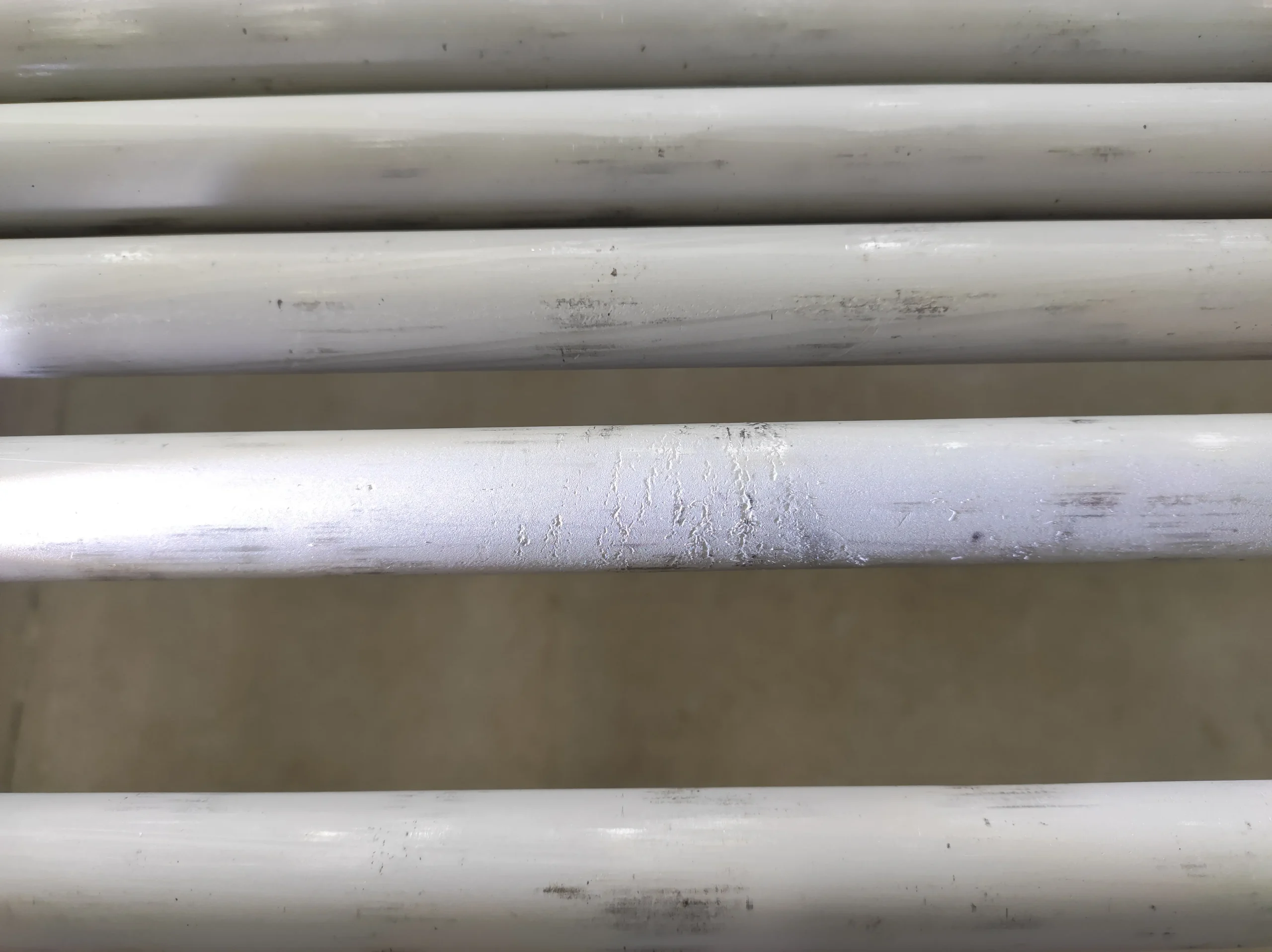

VI. Products