Stainless Steel Lap Joint Stub End General

Stub End – As a kind of butt-weld fittings, it is matched work with lap joint flange. Stainless Steel Stub end and lap joint flanges are used together to effectively reduce pipeline maintenance costs. In a stainless steel piping system or a high grade system, we can select a low grade lap joint flange with stainless steel stub end to be an alternative way to make a flanged connection than welding neck flanges, it is effective to reduce the fabricating cost.

Stainless Steel Stub End can be made from seamless and welded pipe, or stainless steel plates, it is essentially a piece of pipe – one end is flanged and the other is prepared to be welded to a pipe with the same bore size and wall thickness. Therefore, the client should to indicate the SCH / thickness of pipe when ordering.

Types of Stainless Steel Stub End

Stub End has three different types – Type A, Type B, Type C, they are classified by the different “R” – the lap corner. But in actual working, “type A” is the common type as it is matching with lap joint flange specially.

- Type A: To match standard lap joint flange, it is the default type if the client didn’t indicate the type specifically .

- Type B: Stub End B type is mainly used for slip-on flanges and backing flanges, its lap angle is different from “type A”.

- Type C: It can be used either with lap joint flange or slip-on flange. But it is not common type, Kaysuns mainly offer “Type A” and “Type B” stub end.

Long Pattern and Short Pattern

- Short Pattern is also named MSS-A stub end. Compare with long pattern, it is with short pipe but the same lap dimension and thickness. We will quote short pattern to client if the order is not specific.

- Long Pattern type is also named ASA-A stub end. It is much longer pipe and can be used for larger flanges in high pressure class.

- Long Pattern and short parttern stub end are both standard products in ASME B16.9 and MSS SP-43 for lap joint flanges.

The Manfacturing of Stub End for Lap Joint Flanges

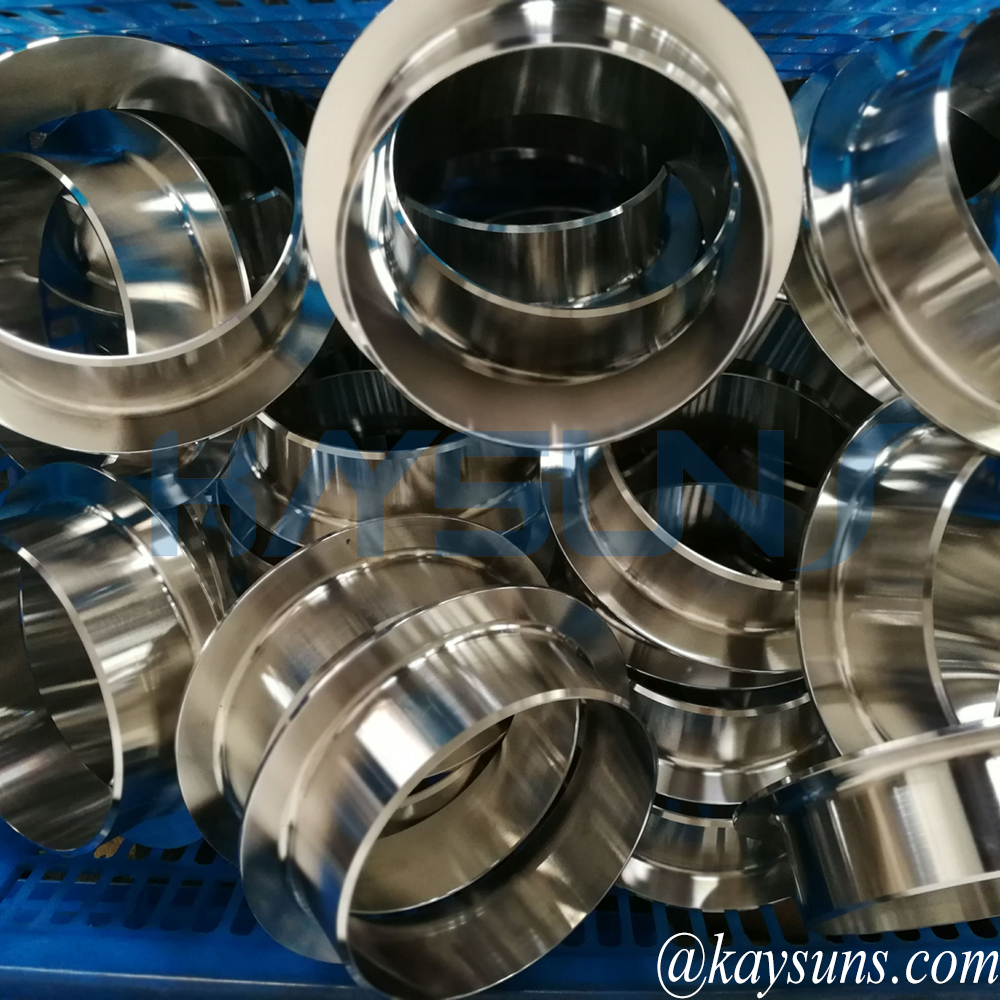

Stainless steel stub end is pressed from pipe by cold forming machine, it can be seamless or welded. The lap is pressed by hydraulic machine for many times, and generally the surface of stub end is machined, so the stub end cost is higher than stainless steel elbows.

Materials of Stub End for Lap Joint Flanges

Our stub ends are stainless steel, duplex steel 2205 (DSS) and super duplex 2507 (SDSS), Inconel alloy, Hastelloy C276, Monel 400, Incoloy 800, copper alloy, titanium alloy etc. We couldn’t do stub end of WPB and other carbon steel.

- Stainless Steel: A403 304/L, 304H 310S, 310H 316/L, 316Ti, 316H 317/L 321/H 347/H S31803 S32750 904L 254SMO (S31254)

- Duplex & Super Duplex: A815 UNS S31803, S32205, UNS S32750, S32760

- Nickel-base Alloy: Alloy 200, Alloy 20, Monel 400, K500, Inconel 600, 625, Incoloy 800, 800H, 800HT, 825, alloy 20, alloy28, hastelloy C22, C276 etc.

Stub End Dimension to ASME B16.9 / MSS SP-43

NPS | OD | T | G | F | R | R |

1/2 | 21.3 | 2.11 | 34.9 | 50.8 | 3.05 | 0.76 |

3/4 | 26.7 | 2.11 | 42.9 | 50.8 | 3.05 | 0.76 |

1 | 33.4 | 2.77 | 50.8 | 50.8 | 3.05 | 0.76 |

1¼ | 42.2 | 2.77 | 63.5 | 50.8 | 4.83 | 0.76 |

1½ | 48.3 | 2.77 | 73 | 50.8 | 6.35 | 0.76 |

2 | 60.3 | 2.77 | 92.1 | 63.5 | 7.87 | 0.76 |

2½ | 73 | 3.05 | 104.8 | 63.5 | 7.87 | 0.76 |

3 | 88.9 | 3.05 | 127 | 63.5 | 9.65 | 0.76 |

3½ | 101.6 | 3.05 | 139.7 | 76.2 | 9.65 | 0.76 |

NPS | OD | T | G | F | R | R |

4 | 114.3 | 3.05 | 157.2 | 76.2 | 11.18 | 0.76 |

5 | 141.3 | 3.40 | 185.7 | 76.2 | 11.18 | 1.52 |

6 | 168.3 | 3.40 | 215.9 | 88.9 | 12.7 | 1.52 |

8 | 219.1 | 3.76 | 269.9 | 101.6 | 12.7 | 1.52 |

10 | 273.1 | 4.19 | 323.9 | 127 | 12.7 | 1.52 |

12 | 323.9 | 4.57 | 381 | 152.4 | 12.7 | 1.52 |

14 | 355.6 | 4.78 | 412.8 | 152.4 | 12.70 | 1.52 |

16 | 406.4 | 4.78 | 469.9 | 152.4 | 12.7 | 1.52 |

18 | 457.2 | 4.78 | 533.4 | 152.4 | 12.70 | 1.52 |

20 | 508 | 5.54 | 584.2 | 152.4 | 12.70 | 1.52 |

24 | 609.6 | 6.35 | 692.2 | 152.4 | 12.7 | 1.52 |

Advantage of Stub End

Reduces the overall cost of the flanged joint:

Generally, the material of stub end is the same as pipeline, but the lap joint flange is of a lower grade, then we can get a lighter product and economic budget for the pipework to instead of a heavy WN flange. Example:

For an super duplex 2507 pipe, instead of using a full A182 F53 welding neck flange, a combination of an SAF 2507 Stub End and a Stainless Steel Lap Joint Flange would do the same exact job, but the total weight of SAF 2507 material would be lower, and the cost as well.

Essentially, stub ends allow to minimize the weight of high-grade material in stainless, duplex, and nickel alloy piping, saving costs. Of course, the bigger the diameter and the class of the flanges, the higher the saving!

Facilitates the installation of the pipeline

After welding joint the pipe and stub end, the lap joint flange still can rotate on the pipe and simplify the alignment of the bolt holes of the mating flanges, so it is more easier for installing.

How to Order

When you want to have a quote, pls clear the information:

Short or Long pattern + Type A or B + SCH/Wall thickness + Size + Material + Standard + Order Quantity

For example, you want to buy 100 pcs stub end for your system and the pipe is 8” SCH40S, long type ,in stainless steel 316L, the piping design is to ASME, so the description would be:

Stub end, Long pattern, Type A, 8” x SCH40S, A403 WP316L, ASME B16.9, 100PCS

Please don’t hesitate to contact us if you have any question.