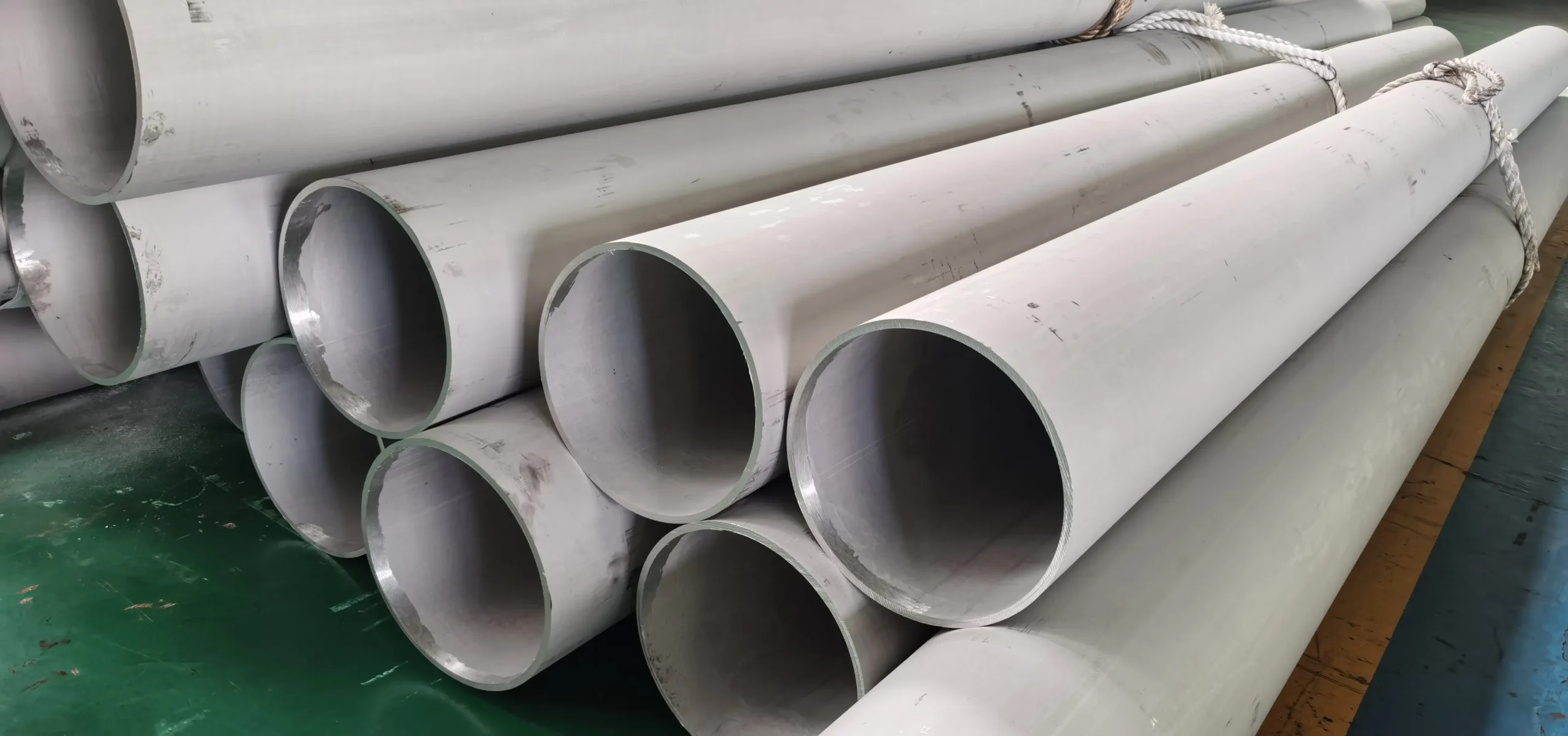

Stainless steel seamless pipe is a long strip of steel with a centrally controlled section and no seams around it. Do you know what are the main production processes? Here, stainless steel pipe and fittings supplier KAYSUNS will give you a brief introduction to the manufacturing process of seamless stainless steel pipes.

In the production process of stainless steel seamless pipes, according to different production methods, they are divided into different types such as hot-rolled pipes, cold-rolled pipes, cold-drawn pipes, and extruded pipes.

- For hot-rolled manufacturing process of seamless stainless steel pipes, they are generally produced on automatic pipe rolling mills. The solid pipes are inspected and surface defects are removed, cut to the required length and centered on the perforated end of the pipes Then it is sent to a heating furnace to be heated and punched on a punching machine. It should be noted that we must continue to rotate and advance while piercing. Under the action of the roller and the plug, the inside of the tube will gradually form a cavity. Meet specifications.

- If we want stainless steel seamless pipes with smaller size and better quality, then we should adopt cold rolling, cold drawing or a combination of these two methods for production. Cold rolling is generally on a two-high rolling mill For cold drawing, it is usually carried out on a single-chain or double-chain cold drawing machine of 0.5~100T.

- For the extrusion method of stainless steel seamless tube, it is generally said that the heated tube blank is placed in a closed extrusion cylinder, and the perforated rod and the extrusion rod move together to make the extruded part extrude from a smaller die hole . Using this method can produce smaller diameter steel pipe.

For this type of steel pipe, it can be divided into two categories: stainless steel seamless steel pipe and stainless steel welded steel pipe, which are also classified according to different processes.