Brief introduction of crevice corrosion test project

Crevice corrosion is the phenomenon that metal surfaces form gaps due to the presence of foreign objects or structural reasons, resulting in accelerated metal corrosion in the gaps.

The width of the slit or gap that causes crevice corrosion must be sufficient to allow the medium to enter and stay in it. When the crevice width is between 25 and 100 μm, it is the most sensitive range for crevice corrosion. In some wider crevices, the corrosive medium is easy flowing, crevice corrosion generally does not occur.

The result of crevice corrosion will lead to a reduction in the strength of the component and a poor fit. The increase in the volume of corrosion products in the crevices will cause local additional stress, which not only makes assembly difficult, but may also reduce the bearing capacity of the component.

Crevice corrosion of metals shows the following main features:

(1) Whether it is the contact of the same or different metals or the contact between the metal and the non-metal, or even some deposits and attachments on the metal surface, as long as there are slits and corrosive media that meet the crevice corrosion, almost all crevice corrosion occurs in both alloys and metals.

Alloys or metals with strong self-passivation ability are more sensitive to crevice corrosion.

(2) Almost all media (including fresh water) can cause crevice corrosion of metals, and the solution containing chloride ions is the most likely to cause crevice corrosion.

(3) The surface of the metal subjected to crevice corrosion can be either comprehensive corrosion or pitting corrosion. Materials with good corrosion resistance usually show pitting corrosion, while materials with poor corrosion resistance usually show full corrosion.

(4) The crevice corrosion has a gestation period, and its length is different due to different materials, crevice structure and environmental factors.( i.e.: The crevice corrosion speed of stainless steel pipes or stainless steel flanges in dry environment will be slower than that in wet environment) The crevices of crevice corrosion are often covered by corrosion products, thereby enhancing the occlusion effect of the crevices.

Test methods and standards of crevice corrosion

| ASTM G48 methodB Crevice corrosion | GB/T 10127 Crevice corrosion |

| ASTM G48 methodD Critical crevice corrosion temperature of nickel-based chromium-containing alloy for bearings | GB/T 13452.4 Filament corrosion test on metal surface |

| ASTM G48 methodF Critical crevice corrosion temperature for stainless steel | GB/T 26323 Filament corrosion test on aluminum and aluminum alloy surface |

| JB/T 5326 Crevice corrosion test of metal materials for instrument |

Crevice corrosion sample requirements

Crevice corrosion sample size requirements: length 50mm, width 25mm, thickness is the actual thickness, preferably 2 ~ 3mm. The surface of the sample must be flat.

Evaluation of seam removal corrosion test

1. Crevice corrosion: weightlessness corrosion rate,

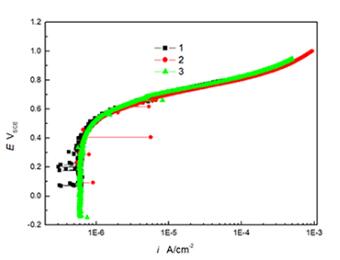

2. Crevice corrosion electrochemistry: corrosion potential, polarization current vs. time curve, corrosion observation

Crevice corrosion sample pictures and test charts

Sample

Test curve