In the coming 2020, the sulfur-limiting order formulated by the International Maritime Organization (IMO 2020) will bring a series of changes to shipping.

According to the latest estimates by the Exhaust Gas Cleaning Systems Association (EGCSA), at least 4,000 ships will be equipped with scrubbers by 2020. Among the various compliance solutions available on the market, exhaust gas cleaning systems (EGCS also known as scrubbers) are a popular choice for existing and new ships. The main reasons for the popularity of this system include economic cost, simple installation, and a relatively short return on investment period.

However, in some cases, installing a scrubber is not feasible. For example, the saving rate for low fuel consumption ships will not be a good idea, so the period of investment return will be longer. In a few cases, space and other technical factors will also decide whether to use a washing tower.

As mentioned above, EGCSA forecast that at least 4,000 ships will be equipped with scrubbers by 2020.

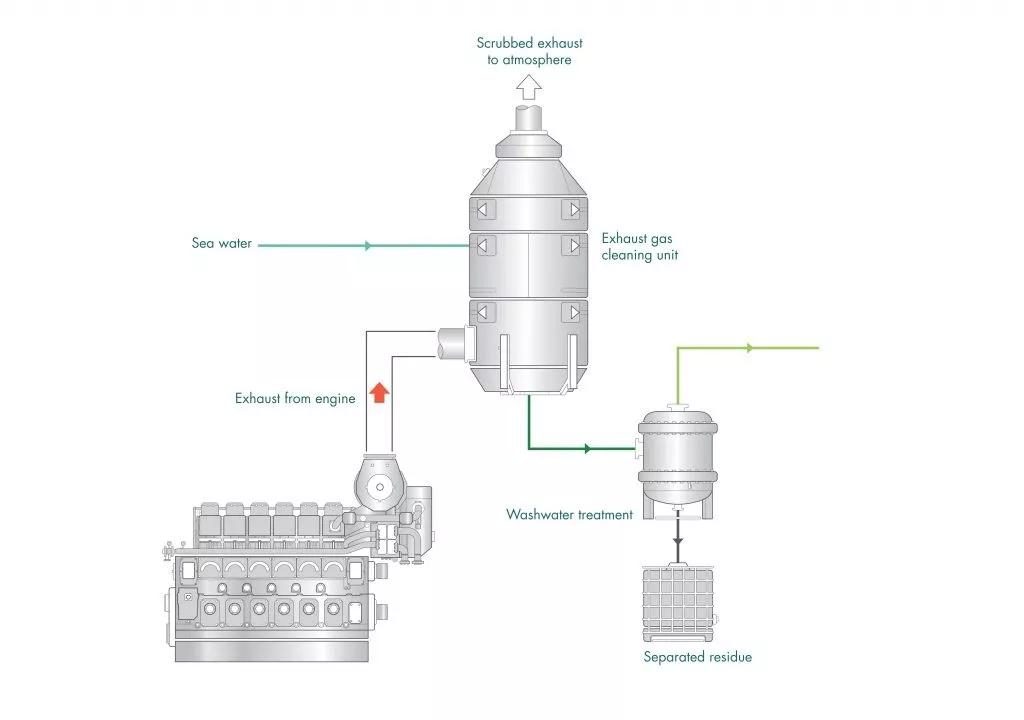

Among them, the large vessels and the ships with higher power are more inclined to install washing tower equipment. Most systems use seawater and discharge the treated and continuously monitored seawater out of the ship, namely open scrubbers.

However, with the decarburization needs of the shipping industry and the development of alternative marine fuels – including zero-emission fuels, the scrubbers cannot be identified as a long-term solution. Some market analysts predict that its service life will not exceed 10 years. But EGCSA has different opinions – The association believes that the demand for washing towers is at least 30 years. The head of the association, Donald Gregory, explained that with the development of new energy sources, the scrubbers “are likely to evolve into more advanced and complex systems, and the life expectancy of the sulfur oxides removing scrubbers is more than 10 years.”

Speaking of the market readiness in 2020, Gregory said that many ship-owners did not do a good job of investigating or only half of it. He believes that there is also uncertainty about fuel prices.

Gregory emphasized, “After using EGCS, the exhaust gas is cleaned, and the particles in the water used for cleaning are treated to ensure that the discharged water meets the strict and sustainable monitoring IMO set limits. Like other organizations, EGCSA also sampled water for test. All examination results have shown that the treated water didn’t exceed the IMO regulations or other standards, such as the World Health Organization (WHO) water quality standards. In addition, a long-term studies carried out by power stations, refineries and the port of Rotterdam, have not identified any impact on water environment which caused by the washing tower water .”

When referring to many problems previously caused by the washing tower, EGCSA said that the problems such as corrosion and water leakage, have been solved through design improvements. After years of development, the current system is made of high-performance stainless steel materials, with an expected service life of more than 39 years.

At present, the main material for exhaust gas cleaning systems include glass-reinforced plastic pipes, special stainless steel, hull coatings, and monitoring equipment. The association states that these materials and systems are reliable and can be used for many years if they are installed by the manufacturers and installers with extensive experience and expertise.

Because the high internal temperature and the harsh corrosive environment of the washing tower, it is necessary to use high performance materials with high corrosion resistance, such as super duplex 2507 stainless steel, 254 super stainless steel and nickel-based alloys. The correct material selection is the core factor to ensure the normal operation of the scrubber. Among the factors that affect the material selection, the most important is the corrosive environment, include temperature, PH value, chloride ion content, etc. In specific cases, nickel alloys such as super stainless steel 254 SMO (S21254) and 2507 super duplex steel dual-phase steel will be recommended.

KAYSUNS think this is good market opportunity for us. We provides qualified classification stainless steel pipe and fittings for our clients. Especially for 254 SMO stainless steel pipe, 2507 super duplex pipe and duplex fittings, our manufacturers are IACS vendor. GL-DNV, BV, ABS, KR etc. are available for our product. We are looking forward to support you getting a reliable but low-cost solution of scrubber materials.