7 Types of Stainless Steel Surface Finish

For most stainless steel pipe fittings manufactures, to improve the surface quality of stainless-steel tubes, they usually improve the surface or change the structure of stainless steel to reduce the energy of stainless steel and the number of medium layers, so that the required stainless steel needed by the customers can be provided. Currently, the most commonly-seen treatment methods for stainless steel surface finish are as follows:

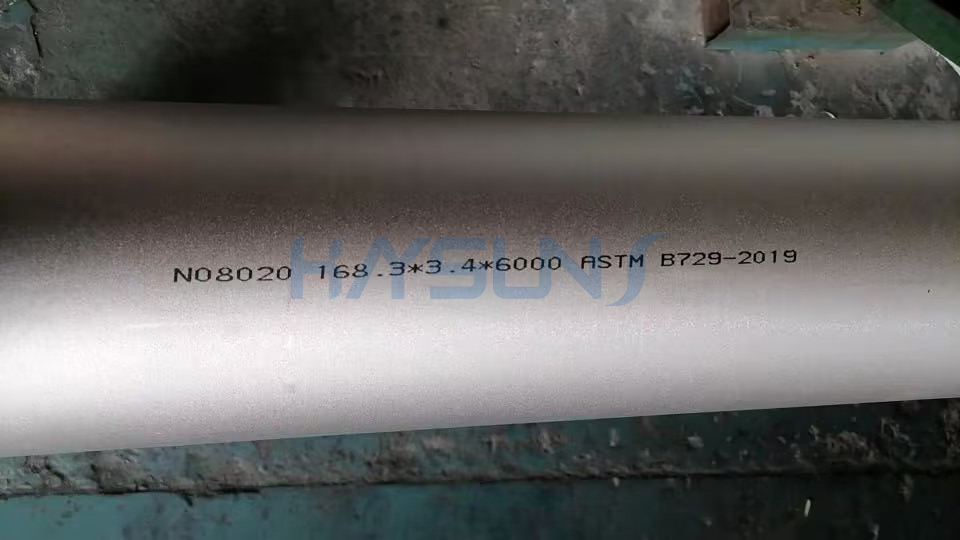

I. AP/CP: Pickled & Passivated

After pickling and passivation of pipes, the roughness of stainless-steel surface will not be improved, but it can remove the surface particles and reduces energy of stainless steel. However, the number of interlayers will not be decreased through this.

AP refers to pickling and passivation. It uses nitric acid and fluorogenic acid solution to remove the oxide layer of steel pipe. For this method, it is cheap and fast. But it may easily cause the grain boundary corrosion, and the internal and external surface will be rough and easy to be attached by suspended impurities.

Pickled surface is also our mill finish for industrial ASTM A312 stainless steel pipe and A403 stainless steel fittings.

II. MP: Mechanical Polishing

This method is often used in the oxidation layer on the stainless steel, and the brightness of effects of holes and scratches will depend on the types of processing. In addition, after mechanical polishing, the stainless steel will be cleaner but its corrosion resistance performance will be reduced accordingly. Therefore, when it is applied in the corrosive environment, it needs to be passivated. And this polishing will lead to material residuals on the surface of stainless steel. Mechanical polishing is the most common type of our food grade stainless steel pipe and fittings.

III. Drawing Polish / Brushed Finish

This method uses precise cold drawing of plugs to improve the roughness of surfaces. It can change the surface structure of stainless steel, but it will not increase morphology, energy and number of interlayers. As the most basic surface treatment process, the mechanical plug draw lays a foundation for other surface treatment processes.

IV. EP: Electro Polishing

Electro polishing refers to the process that treating stainless steel with the anode

This method is achieved through the appropriate adjustment of voltage, current, acid composition, and polishing time under the guidance of electrochemistry.

This method cannot only improve the brightness, smoothness and cleanness of stainless-steel surface, but also strengthen the corrosion resistance of the surface. This is the best way to brighten the surfaces of stainless steel, but its cost and technology are also become higher. However, if there are serious scratches and holes on the surface of the steel pipe, they will become more obvious after electro polishing.

V. BA: Bright Annealing

During bright annealing process, oil is a must for the pumping of steel tubes. However, grain deformation will occur during the process due to grease lubrication, so the oil shall be avoided to be left in the steel pipes.

Apart from cleaning the steel pipe, argon gas can also be used to eliminate deformation during the annealing when it is under high temperature. In the furnace, the surface of the steel pipe can be further cleaned by combining argon with carbon and oxygen combustion.

This method that using the annealing heating and rapid cooling of pure argon gas to brighten the surface is called bright annealing. Though this method can brighten the surface and ensure that the steel tube is fully clean without any external pollution, its surface will feel like foggy when compared with other polishing methods like mechanical polishing, chemical polishing and electro polishing. And the effect is related to the content of argon gas and its heating times.

VI. BP: Buffered Polishing

This method is widely used in the decorative stainless-steel industry to improve the surface brightness. For this method, though the roughness of polished stainless steel can be very good, many cracks can be observed under the electron microscope, and its actual surface is enlarged, as well as some locally isolated ferrite and martensite structures.

However, this method may bring many impurities on its surface, such as abrasive particles. Since the polishing paste is used in this method, a lot of atom energy will be stored in the original depression, leading to an increase for media. Therefore, this kind of pipeline is not allowed to be used in microelectronics, optoelectronics and biopharmaceutical sensitive, corrosive media.

VII. AC: Anodical Cleaning

For some European manufacturers, they will carry out another surface treatment process based on bright annealing to reduce the surface area as much as possible, and thicken the passivation film to improve its corrosion resistance performance, change surface morphology as well as reduce the energy level. For the stainless steels treated with this method, though stainless steel will not have the brightness on the surface, the surface quality will be greatly improved. And it will not produce particles or reduce the composition of iron and iron oxide on the surface.