We are pleased to announce that Kaysuns Ltd. has recently successfully delivered an order of Alloy 20 pipe. These materials will be used in the customer’s major projects. This signifies that our expertise in the field of high-performance alloy materials and our ability to deliver reliably have once again been recognized by our customers. The following is a detailed introduction to Alloy 20 materials and their applications in the industry.

What is Alloy 20 Pipe

Alloy 20 (also known as UNS N08020) is a nickel-iron-chromium based alloy. Known for its excellent corrosion resistance and mechanical properties. Especially suitable for strong acid environments such as sulfuric, phosphoric and nitric acids. Meanwhile, it has good resistance to stress corrosion cracking.

Equivalent Materials of Alloy 20 Pipe

Alloy 20 is a common name. It has corresponding grades in the ASME and EN system.

American Standard (ASME Standard)

Grade: UNS N08020

Standard: ASME SB-729 (seamless and welded pipe), SB-464 (plate, sheet and strip), SB-366 (forgings)

European Standard (EN Standard)

Grade: 2.4660

Standard: EN 10088-3 (corrosion-resistant stainless steel), EN 10216-5 (seamless steel tubes for pressure purposes)

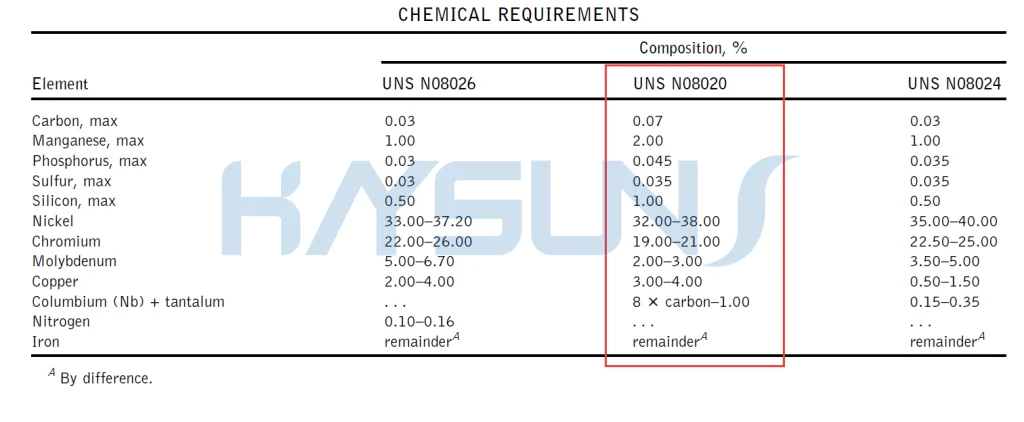

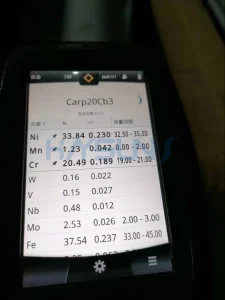

Chemical Composition of Alloy 20 Pipe

Alloy 20 tubing has a chemical composition that allows it to excel in highly corrosive environments, with the following key components:

Mechanical Properties

Alloy 20 pipe not only has excellent corrosion resistance, but also has good mechanical properties, suitable for a variety of industrial applications:

- Tensile strength: ≥550 MPa

- Yield strength: ≥240 MPa

- Elongation: ≥30%

- Hardness: ≤90 HRB

Alloy 20 Pipes / 2.4660 pipes

Applications

Alloy 20 pipe is widely used in the following industries due to its excellent performance:

Chemical Industry

It is used for manufacturing equipment in strong acid environments such as sulfuric acid, phosphoric acid, nitric acid, etc., such as reactors, heat exchangers, pipes and valves.

Oil And Gas

Used for pipelines, pumps and valves under acidic environment (e.g. containing hydrogen sulfide).

Food And Pharmaceutical

For high-purity equipment and piping to ensure non-pollution and corrosion resistance.

Environmental Engineering

For flue gas desulfurization (FGD) systems and wastewater treatment equipment.

Our Capabilities

The successful delivery of this Alloy 20 piping order fully demonstrates Kaysuns Ltd.’s expertise in the field of high-performance alloy materials.

Strict Quality Control:

From raw material procurement to finished product inspection, ensuring that each batch of material meets international standards.

Efficient Supply Chain Management:

Ensure on-time delivery to meet customer’s project schedule.

Technical Support:

Provide customers with comprehensive material selection and technical consulting services.

Kaysuns Ltd. continues to be committed to providing high quality alloy material solutions to our customers. Helping industries to meet complex engineering challenges. After nearly a decade of development, our plant has established a complete production process for seamless nickel-based alloy and specialty stainless steel pipes. In the past 2024, we have successfully delivered several shipments of nickel alloy pipes. These include Hastelloy C276, C22, Incoloy 800H, Monel 400, Incoloy 625 and Alloy 28 seamless and welded pipes. We are looking forward to cooperating with more partners. Hoping to jointly promote technological innovation and industrial development.

If you have any further needs or technical questions about Alloy 20 materials or other high performance alloys, please feel free to contact the team at Kaysuns Ltd.! We will be happy to assist you.