What is Stainless Steel 321

Stainless steel 321 is a stable stainless steel whose main advantage is its excellent resistance to intergranular corrosion in the high temperature range of 800°F to 1500°F (427°C to 816°C) for chromium carbide precipitation. Alloy 321 stainless steel tubing is stabilized by the addition of titanium to form chromium carbide.

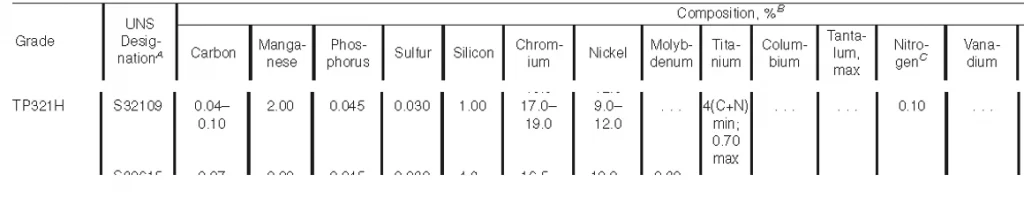

Chemical Compositon of 321 Stainless Steel

Features of 321 stainless steel

321 stainless steel is a Ni-Cr-Mo austenitic stainless steel with properties very similar to 304, but with better resistance to grain boundary corrosion and high temperature strength due to the addition of titanium. Due to the addition of titanium metal, it effectively controls the formation of chromium carbide. 321 austenitic stainless steel has better corrosion resistance in the atmosphere and is widely used in petrochemical, electric power, bridge and automotive industries. 321 stainless steel tube’s ability to resist sensitization, combined with its higher strength at high temperatures, makes it suitable for applications where 304 will sensitize or 304L is not thermally strong enough. 321 stainless steel is not subject to weld decay intergranular corrosion when exposed to mildly corrosive environments. However, welded 321 should never be used in highly oxidizing environments because it is susceptible to “knife line” erosion. However, in environments with operating temperatures above 500° C, 321 is a good choice. Alloy 321 stainless steel tubing has higher creep and stress fracture characteristics than 304 stainless steel tubing. We can consider 321 and 321H stainless steels to be advanced versions of 304 stainless steel. They differ by the addition of very little titanium and 321 also has one more nickel than 304. 321 and 321H differ by their carbon content. The higher the carbon content, the greater the yield strength and the greater the resistance to high temperatures. 321 stainless steel has advantages in high temperature environments due to its excellent mechanical properties. Compared to Alloy 304, 321 stainless steel has better ductility and resistance to stress fracture. TP304L is a more readily available stainless steel material and is less costly than 321. Therefore, if the service environment requires only post-weld intergranular corrosion, 304L is usually preferred. 304L, however, has a lower thermal strength than 321 and is therefore not the best choice if resistance to operating environments above approximately 500°C is required.

Equivalent Grade

- EN: 1.4541

- GB: 0Cr18Ni11Ti

- GOST: 12Х18Н10Т

Standard

- ASTM A240/ASME SA-240M,

- ASTM A276/SA 276M

- ASTM A182/ASME SA-182M

- ASTM A312/ASME SA-312M

- EN 10888

Applications of 321 Stainless Steel

Annealing hoods, high temperature tempering equipment, diesel and heavy vehicle exhaust, firewalls, chimney liners, boiler casings, welded pressure vessels, aircraft components, bellows, oil refinery equipment, fasteners, springs

What We Do With 321 SS

We produce and sell 321 stainless steel tubing, 321 pipe fittings, flanges, and we can supply 321 steel plates, round steel and other products. If you have any questions about 321, please feel free to contact us.