1.4410 vs 1.4462,which is the best one for you?Duplex steels come in a variety of standards and types, and this article describes the main differences between the two common duplex steels.

1.4410 VS. 1.4462 In The Following Spots

Standards

1.4410:

Chinese national standard GB-T standard: digital grade S25073, new grade 022Cr25Ni7Mo4N.

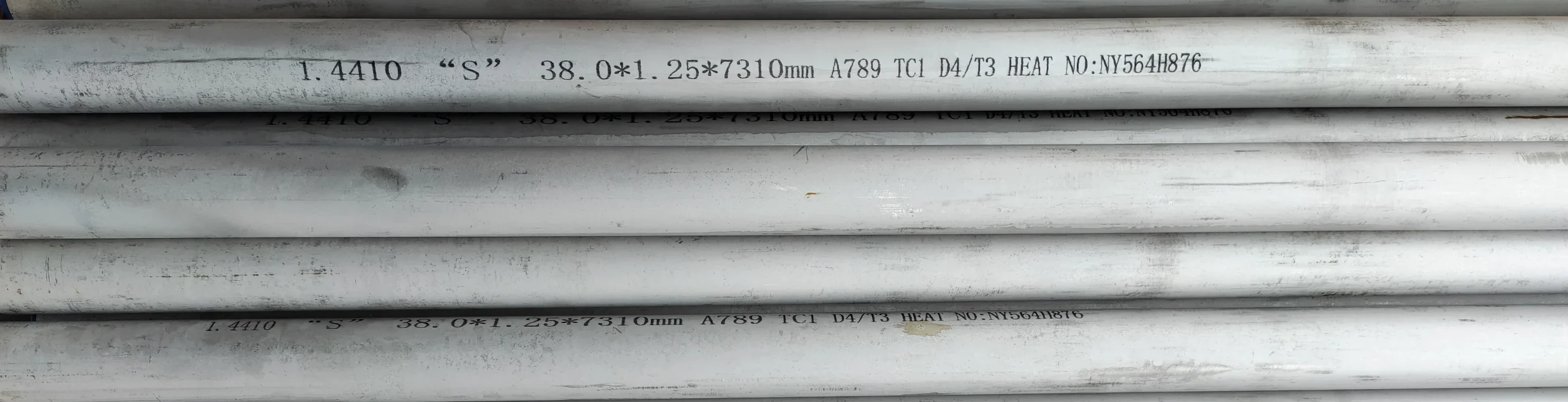

European Standard EN Standard: Conforms to EN 1.4410 and X2CrNiMoN25-7-4.

American Standard ASTM: Known as UNS S32750 in the United States, it conforms to ASTM A240 and A276 standards.

1.4462:

Chinese national standard: corresponding to the domestic 022Cr22Ni5Mo3N duplex stainless steel, the old national standard grade 00Cr22Ni5Mo3N.

German standard DIN: corresponds to DIN 17400.

European standard EN standard: in accordance with EN 1.4462 (also known as X12CrNiMoN225).

American Standard ASTM: Known as UNS S31803/S32205 in the U.S., it conforms to ASTM A240/A240M.

Chemical Composition

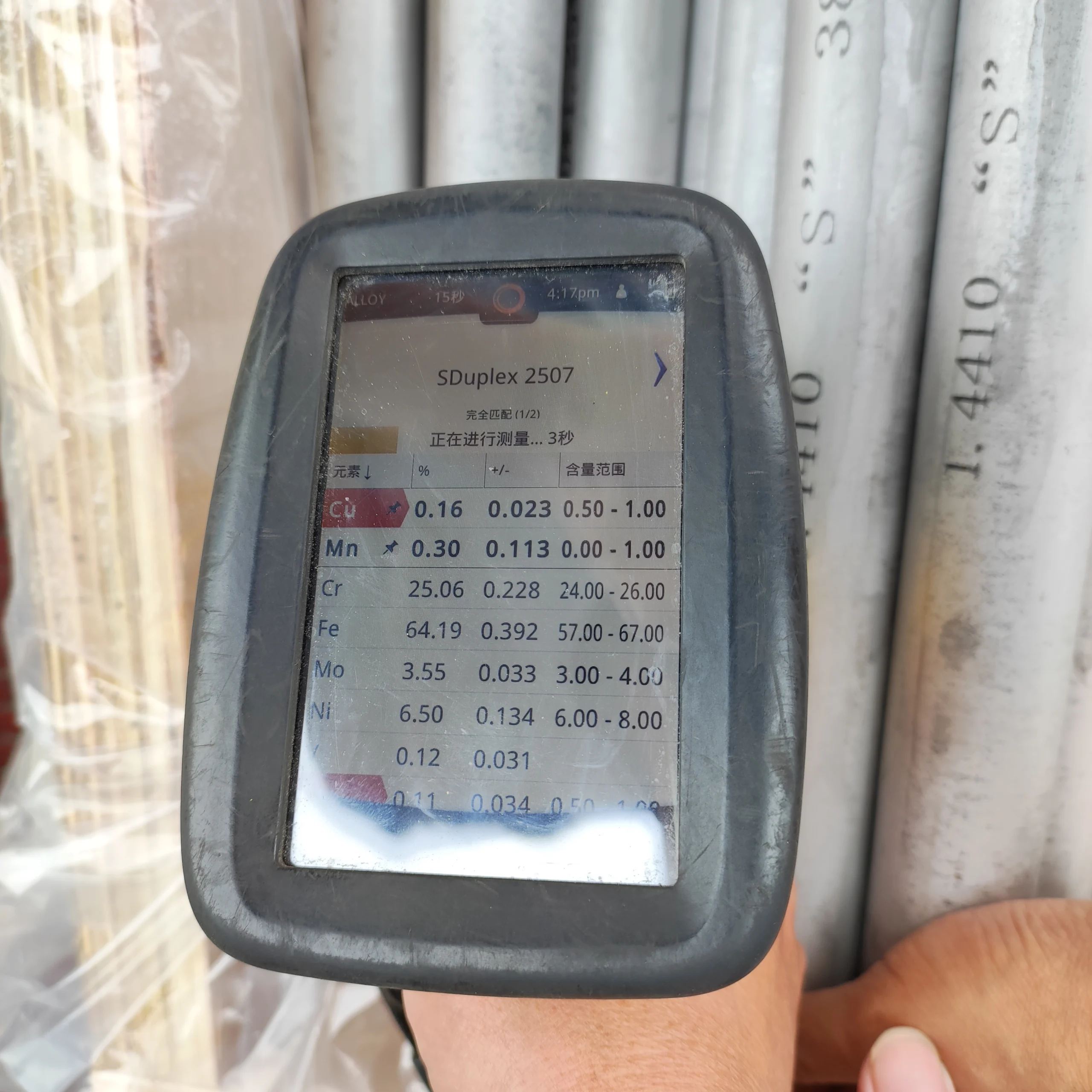

1.4410 is a 2507 super duplex steel, similar to 1.4462 but with higher corrosion resistance. 25% chromium, 7% nickel, 4% molybdenum, and 0.27% nitrogen make up 1.4410.In addition to small amounts of other elements such as carbon, silicon, manganese, and sulfur.

1.4462 is 2205 duplex,it is a typical duplex stainless steel.It is made primarily from elements including 21% chromium, 2.5% molybdenum, 4.5% nickel and nitrogen.And with small amounts of carbon, silicon, manganese and phosphorus.

Duplex steel is an attractive, corrosion-resistant, easy-to-maintain, long-lasting material that can be machined into almost any shape. That is why it is one of the materials for chains, cold-drawn wires, pipes and other components.

1.4410 VS. 1.4462 Pipes In The Following Spots

Mechanical Properties

1.4410 duplex pipe has high strength and high hardness, as well as good toughness. Its tensile strength Rm for 730 ~ 930 MPa, the minimum yield strength Rp0.2 at room temperature for 530 MPa, 380 MPa at 250 ° C. Elongation A (along the) for 25%, notched impact energy (along the) 100 J.

1.4462 duplex pipe also has high strength and good impact toughness, but the specific mechanical property data may vary depending on the specific production process and heat treatment.

Corrosion Resistance

1.4410 super duplex pipe offers excellent resistance to pitting, crevice corrosion and uniform corrosion, resistance to chloride stress corrosion cracking, erosion corrosion and general corrosion in acids, good weldability and high mechanical strength.

1.4462 duplex pipe excels in chloride-containing environments, providing excellent corrosion resistance, especially in marine and chemical processing environments. It is highly resistant to chloride stress corrosion cracking and crevice corrosion for applications requiring high strength and corrosion resistance.

Application

Equipment that handles highly chlorinated solutions typically requires the use of 1.4410 super duplex pipes. For example, in the pulp and paper industry, and in highly chlorinated environments in marine engineering. In addition, it is indispensable in the oil and gas industry, offshore oil platforms and petrochemical plants.

Equipment and components in the chemical industry generally require the use of 1.4462 duplex pipes. Even nuclear power cooling water systems can use it.

1.4410 VS. 1.4462 Summary

1.4410 Super Duplex and 1.4462 Duplex are very different in terms of both the material itself and the tubing made from it. These differences give them their own advantages and suitability for different applications. When selecting a material, a decision needs to be made based on the specific application requirements, operating environment and cost factors.

What we do of Duplex 1.4462 and Super Duplex 1.4410

- Round Bar

- Sheet / Plate

- Forging / Flange

- Pipe & Pipe Fittings